CONCRETE ESTIMATING AND TAKEOFF SERVICES

Concrete estimating is about figuring out how much concrete you need and how much it will cost. You look at project plans and measure dimensions to make accurate calculations. It’s important to consider extra factors like waste and changes in material prices. Accurate estimation helps keep the project on budget and schedule, preventing delays or shortages.

Dekr Estimation has been offering concrete estimating services for years. We work with general contractors, concrete contractors, home builders, and real estate developers. Contractors often find it hard to estimate costs for sidewalks, driveways, and paving while working onsite. We help by providing accurate, concrete estimates and takeoff services. This makes it easier for them to prepare bids.

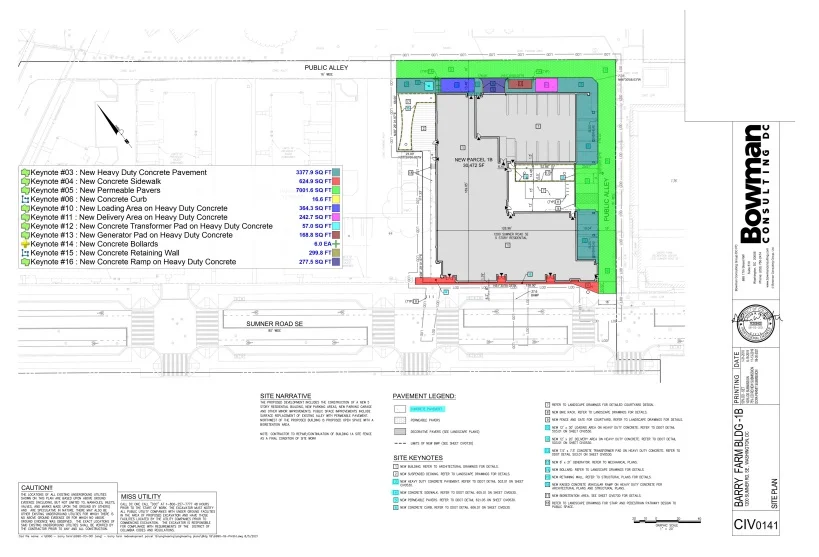

Concrete Estimating Samples

Upload your Concrete Estimation Plan

HOW TO BEGIN WITH US!

OUR PORTFOLIO IN CONCRETE TAKEOFF SERVICES

- Dams

- Highways

- Bridges

- Driveways

- Culverts And Sewers

- Commercial Buildings

- Marine Structures

- Fences

- Residential Buildings

- Foundations For High Rise Buildings

Concrete Estimating Services Includes:

- Expert Witness

- Litigation Assistance

- Bid Preparation

- Budget & Bid Estimates

- Design Estimates

- Project Lead Generation

- Value Engineering

- Change Order Estimates

We've had the pleasure of assisting a wide range of construction businesses, from large companies to small enterprises. Our clients include general contractors, concrete contractors, asphalt contractors, foundation contractors, vendors, and pavers. Known for our precision, we offer highly detailed concrete estimating services and material takeoffs, earning a solid reputation in the industry.

Our success extends to providing concrete takeoff services for diverse projects such as sidewalks, driveways, retaining walls, concrete pavements, waterproofing, parking lots, flatwork, basements, concrete foundations, curbs, slabs, and more. We've catered to both private and public projects, ensuring accuracy and reliability every step of the way.

Offer:

IF YOU ARE FROM USA THEN GET

30% OFF ON YOUR FIRST ESTIMATE!

Just upload your plans, We will review them and send a quote in the next 5 minutes.

THE RANGE OF CONCRETE ESTIMATING SERVICES

- Concrete Quantity Takeoffs

- Value Engineering

- Budget & Bid Estimates

- Project Lead Generation

- Bid Preparation

- Design Estimates

- Expert Witness

- Change Order Estimates

- Litigation Assistance

- Concrete Contractor Marketing

Our deliverables for division 3 trade include:

- Concrete takeoff spreadsheets

- Material, labor & equipment costs

- Man Hours

- Marked up drawing plans

- Takeoff summary including total costs for material, labor, equipment, overhead, profit, etc

- Review of exclusions and inclusions

Outsource Concrete Estimates

Contractors working on paving, driveways, and sidewalks are often too busy on-site to estimate costs accurately. This can lead to overbidding or underbidding projects. To win jobs with the best bid, you need precise estimates for costs and man-hours. Outsourcing your estimating to a professional company like ours ensures accuracy and offers these benefits:

- You won’t miss out on any opportunities.

- Expert estimators boost your efficiency and profit potential.

- Outsourcing saves you the expense of a full-time estimator.

- You don’t need to buy costly software or hire and train staff for concrete estimating.

- It increases your bid volume. Professional services help you bid on more projects and win more.

Request a Free Call Back

Request a Free Call Back today and discover how our services can elevate your experience.

Benefits of Outsourcing Concrete Takeoff

- Ensure you never miss out on valuable opportunities.

- Save on hiring and maintaining a full-time concrete estimator.

- Increase your bid volume and win more projects with our professional support.

- Avoid the cost and complexity of purchasing expensive software and training in-house staff.

Scope of work of a building grey structure below plinth level (Substructure)

In a high-rise building project in the USA, the "Scope of Work for Grey Structure Below Plinth Level" covers work on the parts below the plinth level. This includes the basic framework like foundations, sub-grade walls, and columns. These elements are important for supporting the building.

Here’s a detailed Scope of Work for concrete work below the plinth level in a high-rise building project:

1. Site Preparation and Excavation (Early Works)

Site Clearing: Remove all vegetation, debris, and existing structures from the site. This prepares the area for excavation and construction work.

Excavation: Dig out the soil to create the necessary trenches and foundations for the building. This includes removing soil to the required depth for foundations and sub-grade structures.

Shoring and Bracing: Install temporary supports to prevent soil collapse and ensure the stability of the excavation site. This is crucial for deep excavations and protecting workers.

Piling: Drive piles into the ground to support the structure’s foundations. Piles are used to transfer the load of the building to more stable soil or rock layers below the surface.

Shotcrete: Apply a layer of sprayed concrete to stabilize excavated areas and form structural elements. Shotcrete is used to reinforce soil and create smooth, durable surfaces in challenging conditions.

2. Dewatering and Water Management

Dewatering: Remove excess groundwater from the excavation site to keep it dry and stable. This involves using pumps or wells to lower the water table and prevent water accumulation that could affect construction.

Waterproofing: Apply protective layers or coatings to prevent water infiltration into structural elements. This is essential for keeping foundations and sub-grade walls dry and ensuring long-term durability.

3. Foundation Work

Footings

Design: Plan the shape and size of the footings based on load requirements and soil conditions. This ensures the foundation can support the building properly.

Formwork: Construct temporary molds or frameworks to shape and hold the concrete in place while it sets. This helps create the correct footing dimensions.

Reinforcement: Install steel bars or mesh within the formwork to strengthen the concrete and improve its load-bearing capacity.

Concrete Pouring: Pour and level the concrete into the formwork to create the footings. Allow it to cure and set to achieve the necessary strength.

Footing Beams

Formwork: Build temporary molds to shape the footing beams. This provides a precise outline and supports the concrete until it hardens.

Reinforcement: Place steel bars or mesh within the formwork to strengthen the beams. This reinforcement helps the beams handle structural loads effectively.

Concrete Pouring: Pour concrete into the formwork to create the footing beams. Ensure it is evenly distributed and compacted, then allow it to cure and gain strength.

Mat Foundation

For high-rise buildings, a mat or raft foundation may be used.

Formwork and Reinforcement: Build extensive formwork to shape the large mat foundation. Place steel reinforcement bars or mesh within the formwork to provide strength and support for the entire foundation.

Concrete Pouring: Pour concrete over the prepared formwork and reinforcement to form the mat foundation. Ensure proper distribution and compaction of the concrete, and allow it to cure thoroughly for strength.

4. Basement Construction

Basement Walls

Formwork: Set up molds or panels to shape the basement walls. This temporary structure holds the concrete in place until it sets and gains strength.

Reinforcement: Install steel bars or mesh inside the formwork to strengthen the walls. This reinforcement helps the walls handle loads and resist cracking.

Concrete Pouring: Pour concrete into the formwork to create the basement walls. Ensure the concrete is evenly distributed and properly compacted, then allow it to cure and harden.

Basement Floors

Formwork and Reinforcement: Set up molds or panels to shape the basement floor. Install steel reinforcement bars or mesh within the formwork to strengthen the floor and prevent cracking.

Concrete Pouring: Pour concrete into the formwork to create the basement floor. Ensure it is evenly spread and properly compacted, then let it cure to achieve the desired strength.

5. Structural Elements

Columns:

Formwork: Construct molds to shape the columns. These temporary structures hold the concrete in place until it sets.

Reinforcement: Place steel bars or mesh inside the formwork to strengthen the columns. This reinforcement is crucial for supporting the building's loads.

Concrete Pouring: Pour concrete into the formwork to form the columns. Ensure even distribution and proper compaction, and allow the concrete to cure thoroughly.

Slab & Beams

Formwork: Set up molds to shape the slabs and beams. These temporary structures support the concrete until it hardens and gains strength.

Reinforcement: Install steel bars or mesh within the formwork for slabs and beams. This reinforcement adds strength and helps the structural elements bear loads.

Concrete Pouring: Pour concrete into the formwork for slabs and beams. Ensure it is evenly distributed and properly compacted, then allow it to cure and harden.

6. Concrete Finishing and Curing

Surface Finishing: Smooth and level the concrete surface once it has partially set. This may involve troweling, brushing, or other techniques to achieve the desired texture and appearance.

Curing: Maintain the moisture and temperature of the concrete to ensure proper hydration and strength development. This can involve covering the surface with wet burlap, plastic sheeting, or using curing compounds.

Scope of work of a building grey structure above plinth level (Super Structure)

In construction, "above plinth" means the part of the building above the ground floor or base level. Concrete work here involves various construction activities done above this level. Here’s what this usually includes:

1. Concrete Slabs:

Floor Slabs: Pour concrete to create the flat surfaces of floors within the building. This involves setting up formwork, placing reinforcement, and ensuring a smooth finish.

Rooftop Slabs: Pour concrete to form the flat surface of the building's roof. This process includes setting up formwork, adding reinforcement, and finishing the surface to ensure it can support the intended loads and weather conditions.

2. Concrete Walls:

Load-Bearing Walls: Pour concrete to create walls that support the weight of the structure above them. These walls are essential for the building’s stability and require precise reinforcement and formwork.

Partition Walls: Construct concrete walls to divide interior spaces within the building. These walls provide separation but do not support structural loads.

Core Walls: Build central concrete walls that house elevators, stairwells, and utility shafts. These walls are key to the building’s structural integrity and vertical circulation.

Shear Walls: Pour concrete to create walls designed to resist lateral forces, such as wind or seismic activity. These walls help stabilize the building and prevent it from swaying or collapsing.

3. Beams and Columns:

Beams: Pour concrete to form horizontal structural elements that support loads from floors or roofs. Beams transfer weight to columns and walls, requiring accurate formwork and reinforcement.

Columns: Create vertical concrete supports that transfer loads from beams and slabs to the foundation. Columns must be reinforced and precisely formed to ensure they can handle structural stresses.

4. Stairs and Ramps:

Staircases: Pour concrete to form the steps and supporting structure of staircases. This includes setting up formwork, placing reinforcement, and finishing to ensure safety and durability.

Ramps: Construct concrete ramps to provide accessible paths between different levels. This involves shaping the ramp, reinforcing it, and ensuring it meets design and safety standards.

5. Lintels and Overheads:

Lintels: Install concrete beams above openings like doors and windows to support the weight of the structure above. Lintels are reinforced and placed to distribute loads and prevent cracking.

6. Surface Finishes:

Floor Finishes: Apply treatments to the concrete floor to achieve the desired appearance and functionality. This can include polishing, staining, or adding texture to enhance durability and aesthetics.

Wall Finishes: Apply coatings or treatments to concrete walls to improve their appearance and protect them from damage. This may involve painting, plastering, or texturing to achieve a smooth or decorative surface.

7. Structural Reinforcement:

Reinforcement Bars (Rebars): Install steel bars within concrete to strengthen it and help it withstand tension and shear forces. Rebars are placed according to design specifications to improve the concrete’s load-bearing capacity and durability.

8. Formwork and Shuttering:

Formwork: Construct temporary molds or frames to shape and support the concrete while it sets. Formwork holds the concrete in place and ensures it cures to the desired shape and dimensions.

9. Waterproofing and Insulation:

Waterproofing: Apply protective layers or coatings to concrete surfaces to prevent water infiltration. This helps keep structures dry and prevents damage from moisture.

Insulation: Install materials to reduce heat transfer through concrete walls, floors, or roofs. Insulation helps improve energy efficiency and comfort by maintaining desired temperatures inside the building.

10. Concrete Finishing and Curing

Surface Finishing: Smooth and shape the concrete surface after pouring. Techniques include troweling for a sleek finish, brushing for texture, or applying special treatments to achieve the desired look and functionality.

Curing:

Top of Form: Apply curing methods to the top surface of the concrete to maintain moisture and promote proper hardening. This can include covering with wet burlap, using curing compounds, or applying plastic sheeting to prevent the concrete from drying out too quickly.

Bottom of Form: Ensure proper curing at the bottom of the formwork to prevent premature drying and ensure even strength development. This may involve maintaining moisture with wet coverings or applying curing compounds to keep the concrete hydrated until it fully sets.

Our Concrete Estimation Process

The concrete estimation process begins with studying the client's drawing plans to understand the work needed. Next, we use digital software like Bluebeam, Planswift, or Accubid to perform an on-screen takeoff. The quantities are then recorded in Excel spreadsheets with detailed descriptions.

Our concrete takeoff spreadsheet includes a breakdown of all these quantities:

- The spreadsheet lists the amount of concrete needed for slabs, piers, footings, headers, beams, walls, columns, lintels, platforms, steps, and more. It also includes estimates for transportation costs and equipment like cranes, pumps, and mixers.

- It details the costs for concrete formwork, including whether you buy or rent it, repairs, associated equipment, transportation, and labor.

- Concrete reinforcements such as rebar, wire mesh, plastic mesh, stirrups, dowels, and anchors are also included.

How to win Concrete Estimation projects in 2024/25

Win concrete estimation projects in 2024/25 with Dekr Estimation. We use advanced software for accurate and detailed takeoffs. Our team stays updated on industry trends and material costs to give you competitive estimates. We focus on clear communication and great service to build strong client relationships. Partnering with us means better bids and more project wins.

Dekr Estimation provides concrete estimation services in United States regions. In the US, we serve in the following markets: Illinois, Georgia, New York, North Carolina, Minnesota, Colorado, Arizona, Indiana, Louisiana, Maryland, Alabama, Washington, New Jersey, California, Connecticut, Oklahoma, Virginia, Oregon, Nebraska, Alaska, Arkansas, Delaware, Minnesota Idaho, Iowa, Mississippi, Montana, Nevada, Wyoming, New Hampshire, Utah, Florida, Massachusetts, South Carolina, Texas, Missouri, Kentucky, Pennsylvania, Michigan, Tennessee, Ohio, Wisconsin, Vermont, Hawaii.